After years of operation in an unstable geopolitical and economic reality, representatives of the industrial sector are beginning to look more optimistically at the future. Producers seeking new development opportunities are increasingly reaching for tools used for digital transformation, such as the internet of things, generative AI, or metaverses. According to the report “2024 Manufacturing Outlook”, prepared by consulting firm Deloitte, globally every fifth representative of the industrial sector already uses metaverse technology. The benefits of digitizing basic processes in manufacturing companies remain unchanged: improving efficiency, increasing supply chain resilience, improving competitiveness and reducing production emissions.

The latest Deloitte publication reveals current trends in the manufacturing industry and presents the moods of industry representatives about the near future. The phenomena described primarily concern the role of modern technologies such as artificial intelligence or metaverses in industry, the digitalization of supply chains and the issue of decarbonization of the production process.

The publication’s authors indicate that at the beginning of 2024, there is cautious optimism in the industry, cooled by weaker PMI readings than expected in December 2023 and January 2024. After several difficult years, marked by a lack of stability and supply chain disruptions, the industry seems to be returning to growth. This is a crucial signal, especially for the Polish sector, which has been developing at a pace three times the EU average since 2004, and has one of the highest shares in the national GDP among all EU countries.

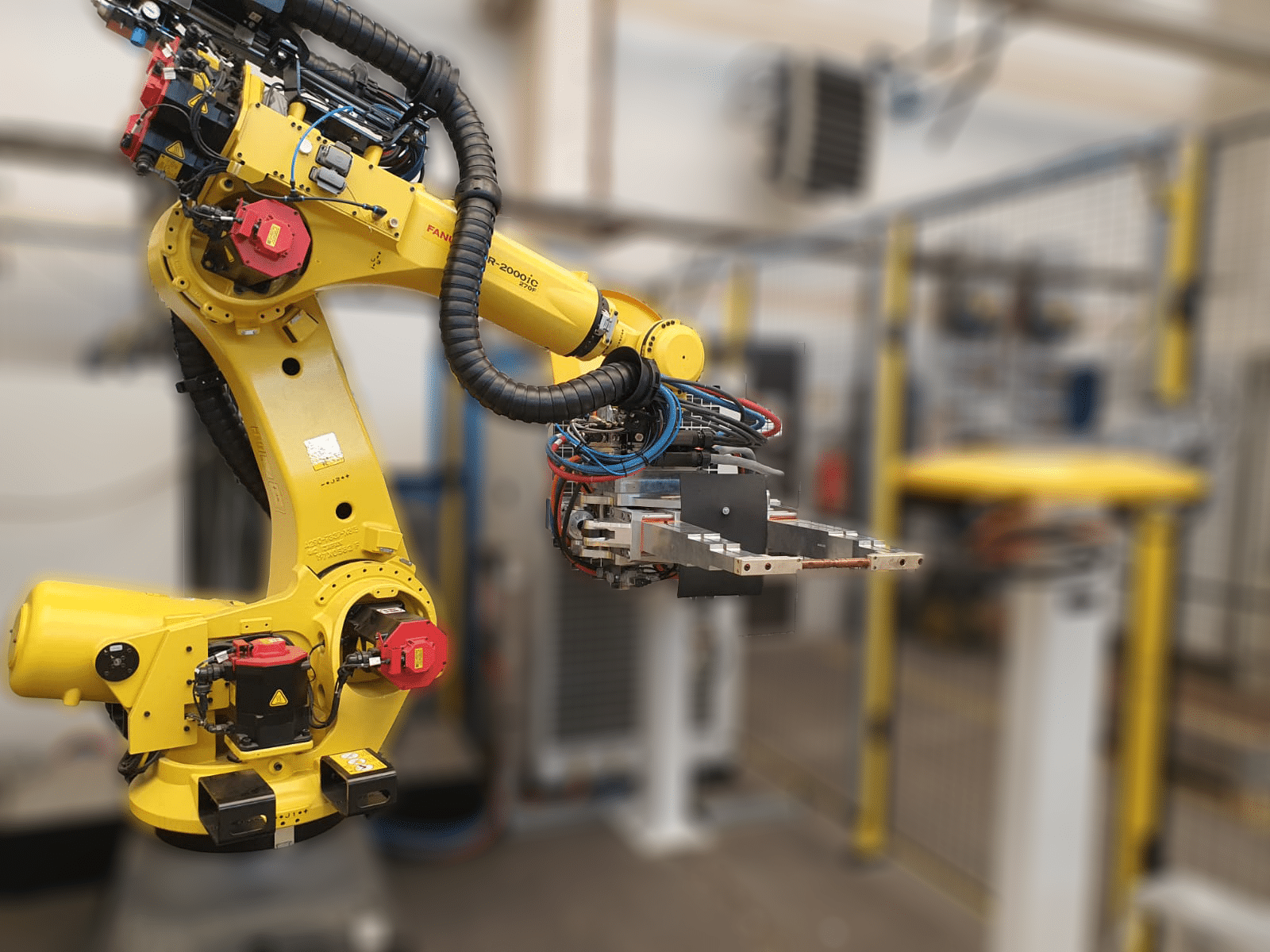

Factories are becoming smarter

The pursuit of maximizing the efficiency of the production process is the main reason for the growing popularity of digital technologies in the industry. A manifestation of this phenomenon is the gaining importance of the concept of smart factories, or production plants that increasingly use tools such as the internet of things, generative AI, or metaverse. According to the report’s authors, the application of the latest technology beneficially affects, among others, the production process’s flexibility and the organization’s efficiency. Manufacturers using smart solutions have reduced production costs by a third and improved the quality of the products produced by 20%.

Increasing number of digital twins

One of the most significant challenges for industry in recent years has been the stability of supply chains. Any disruptions in the supply area have far-reaching impacts. To avoid similar incidents in the future, 76% of the respondents claim to be analyzing their supply ecosystems using the latest technology, enabling them to identify sensitive areas of business. An example of this trend is the growing popularity of the digital twin concept.

Technology in the service of decarbonization

In addition to challenges related to stability and resilience, the manufacturing sector is grappling with reducing the emissions of its activity. Key to the decarbonization process is maximizing energy efficiency, Deloitte experts say. Energy demand reduction starts from effective energy consumption monitoring, which also plays a critical role in digital tools.