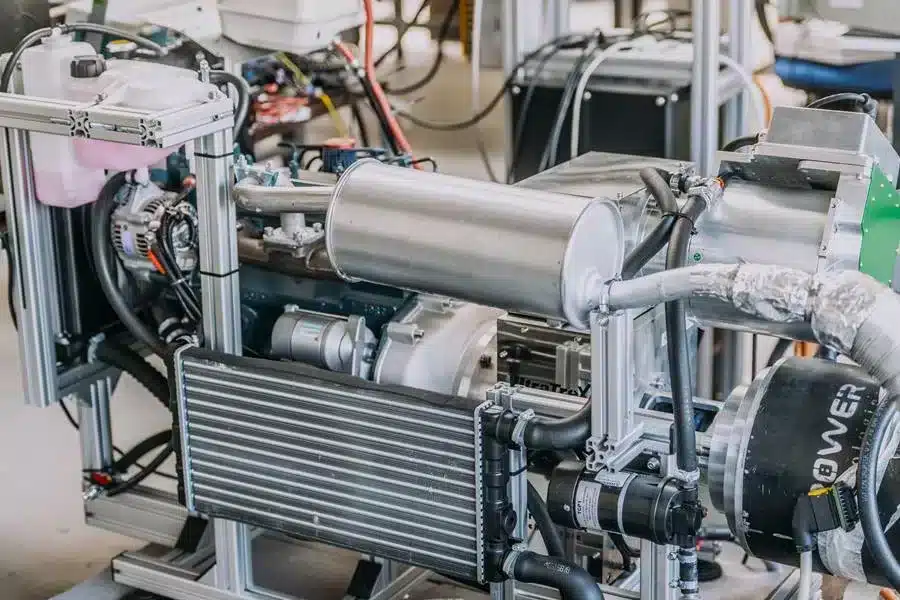

The Szczecin-based firm has developed another innovative propulsion system. The new solution is a hybrid, designed with working water units in mind. It combines a traditional diesel engine with an advanced electric system, significantly improving the efficiency, economy, and ecology of these machines’ operation.

Marine work vehicles in many regions, including Asia, play a huge role for ports. These machines are used for tasks such as clearing waterways that rapidly overgrow in tropical conditions, making navigation dangerous or impossible. They also work as waterborne ‘garbage trucks’, collecting waste pieces of wood and other pollutants from the water surface that hinder maneuverability, often pollute the air, and spoil the view. Other applications for this drive may include small port cranes, transport units, or auxiliary units.

“Traditional machines powered by diesel engines have long struggled with issues related to high fuel costs, increasing costs of emission reduction systems, and limited efficiency in challenging conditions. Many ports, especially in tourist-friendly cities, are also striving to minimize the nuisance related to diesel engines. mPower, recognizing these challenges, has developed a solution that not only increases the efficiency of such drives, but also reduces their negative impact on the environment. In many regions of Asia, ecology and innovation are becoming increasingly important on the water,” reveals Marcin Hołub, President of mPower.

The new drive was ordered by a Malaysian manufacturer of combines and work machines, who sees the future in the technological solution developed by the Szczecin-based company. The first built drive will soon be installed in the first combine, and the manufacturers also plan to promote their prototype at technology fairs in Jakarta, Asia.

“Our system utilizes a hybrid, parallel connection of the diesel engine and electric system, which allows a significant reduction in exhaust emissions and fuel consumption optimization,” explains Marcin Hołub. “As both systems complement each other, fuel consumption is lower, which reduces operating costs. Also, when there is an opportunity to charge the system at the wharf, we offer a plug-in hybrid option, resulting in further savings. The machine can operate in pure electric mode for as long as the battery charge status allows, e.g., during maneuvering, leaving the port, loading, or unloading. It’s easy to imagine such a hybrid as a transitional stage in small excavators or yachts. The presence of a diesel engine does not limit the machine’s working time or require immediate expansion of the charging infrastructure,” he adds.

This isn’t the first time mPower has surprised the marine industry with its technological solutions. The company made a name for itself last year when it, together with CS Composites, created a compact hydrogen fuel cell, powering a motorboat under 6 meters long. No one had built such a drive before.

“Our engineering achievements have not gone unnoticed,” says Marcin Hołub with a smile. “There is considerable interest in new solutions, especially given that mPower is able to create customer-specific technology solutions for specific customer applications. An example might be a multifunctional, utility-transport catamaran for the Polish Academy of Sciences with a multi-fuel drive, for which we designed and built a system based on a hydrogen fuel cell and energy management system,” he explains.

The Szczecin company also continues to work on the development of additional technologies that may contribute to an even greater transformation of drives on the water.

Source: https://managerplus.pl/szczecinski-mpower-dostarczy-pierwszy-hybrydowy-naped-do-azji-54103